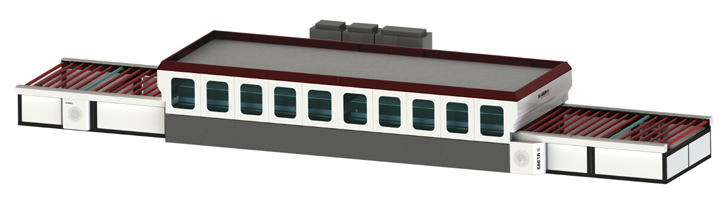

The PVB/EVA Glass Laminating Machine (Laminated Glass Laminator) is engineered for glass processors who prioritize safety, speed, and stable, repeatable quality. By adopting an autoclave-free lamination process, the system fundamentally removes the high-pressure vessel risk associated with traditional autoclaves—improving operational safety while reducing overall system complexity and capital requirements. The machine supports a broad range of interlayer options, including standard PVB film and EVA film, enabling flexible production across different product types and customer specifications.

Designed for high-efficiency manufacturing, the machine completes a full lamination cycle in just a few minutes, helping factories shorten lead times and meet fast delivery demands without compromising consistency. The entire workflow is governed by a fully automated industrial PC control system, providing intuitive operation, clear parameter management, and dependable repeatability—while reducing reliance on highly skilled labor. In addition, the process does not require strict humidity control, avoiding the need for climate-controlled rooms and cutting labor, energy, and operating costs. As a self-contained unit, it can run independently without dependence on extensive auxiliary facilities or equipment, delivering a practical, streamlined solution for modern laminated glass production.

Features:

- Autoclave-Free Lamination – Eliminates the need for a high-pressure autoclave, removing autoclave-related safety risks at the source.

-

High-Speed Production Cycles – Completes a full lamination cycle in just a few minutes, enabling rapid turnaround and fast customer delivery.

-

Multi-Interlayer Compatibility – Works seamlessly with multiple interlayer films, including standard PVB and EVA (and other commonly used films).

-

No Strict Humidity Control Required – Operates reliably without a climate-controlled room; significantly reduces environmental conditioning requirements.

-

Fully Automated Industrial PC Control – End-to-end automated processing with recipe/parameter management for consistent, repeatable results.

-

Simple, Operator-Friendly Operation – Intuitive workflow that minimizes training time and reduces reliance on highly skilled labor.

-

Standalone, Self-Contained System – Runs independently without heavy dependence on auxiliary facilities or additional equipment.

-

Flexible Output for Any Order Mix – Suitable for both batch production and single-piece processing, delivering exceptional versatility.

-

Lower Labor and Energy Demand – Reduced staffing needs and lower energy consumption thanks to automation and simplified facility requirements.

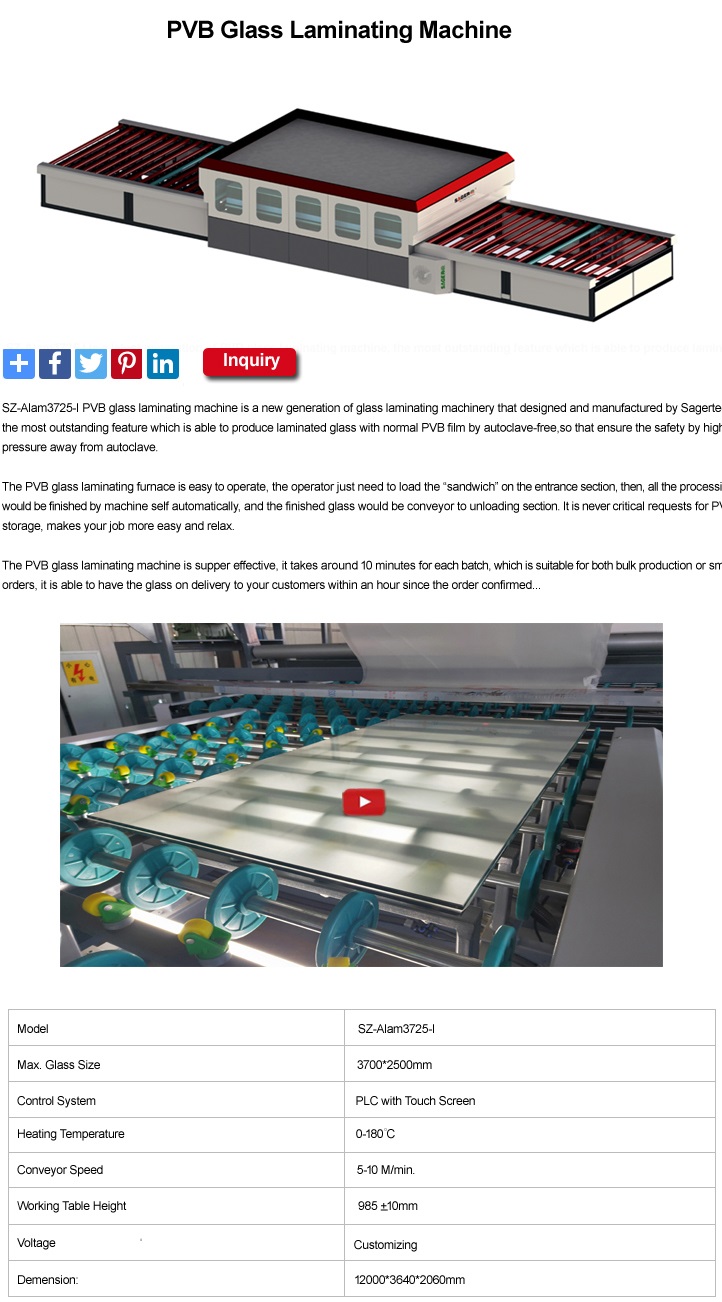

| Model/Series | ALAM Pro |

| Max. Glass Size | 3700*2500mm , 4200*2600mm, 5200*2600mm |

| Control System | PLC with touch screen |

| Heating Temperature | ~160℃ |

| Conveying Speed | 5-10m/min. |

| Working Table Height | 985mm |

| Voltage | Customizable |

| Dimension | 16000*3600*2100mm |

FRQ — PVB/EVA Autoclave-Free Glass Laminating Machine

Q1: What is this PVB/EVA glass laminating machine used for?

A: It is an autoclave-free laminated glass machine designed for efficient laminated glass production using multiple interlayer films, including standard PVB film and EVA film.

Q2: Does this laminated glass machine require an autoclave?

A: No. This is an autoclave-free glass laminating machine, which completes the lamination process without a high-pressure autoclave—eliminating autoclave-related risks at the source.

Q3: Why choose an autoclave-free laminated glass laminator?

A: An autoclave-free laminated glass laminator removes the need for high-pressure vessel operation, improves operational safety, reduces system complexity, and streamlines daily production management.

Q4: Which interlayer films are compatible with this glass laminator?

A: The machine is compatible with multiple interlayers, including standard PVB interlayer film and EVA interlayer film, enabling flexible production for different laminated glass specifications.

Q5: How fast is the production cycle?

A: The machine is engineered for fast throughput, completing a full lamination cycle in just a few minutes, supporting rapid order turnaround and quick customer delivery.

Q6: Is a climate-controlled humidity room required for PVB/EVA lamination?

A: No. This PVB/EVA laminated glass machine is designed to run reliably without a dedicated climate-controlled room, reducing strict humidity-management requirements in typical operations.

Q7: Is the process fully automatic?

A: Yes. The system uses industrial PC control to enable fully automated processing, with recipe/parameter management for consistent, repeatable laminated glass results.

Q8: How easy is it to operate this laminated glass machine?

A: The workflow is designed for simple, intuitive operation, reducing training time and lowering dependence on highly skilled labor in day-to-day laminated glass manufacturing.

Q9: Can this glass laminating machine run as a standalone unit?

A: Yes. The equipment is designed as a standalone laminated glass machine, minimizing reliance on complex auxiliary facilities or additional equipment.

Q10: Is it suitable for both batch production and single-piece processing?

A: Yes. This PVB/EVA glass laminator supports both high-volume production and single-piece processing, making it ideal for mixed orders and custom projects.

Q11: How does automation help laminated glass quality and consistency?

A: With computer-controlled lamination, key parameters are executed consistently, reducing operator variability and improving repeatability across shifts and production runs.

Q12: How does this machine help reduce labor and operating costs?

A: By combining autoclave-free lamination, minimal humidity-control requirements, and full automation, the system reduces manual intervention, lowers energy demand, and simplifies facility needs.