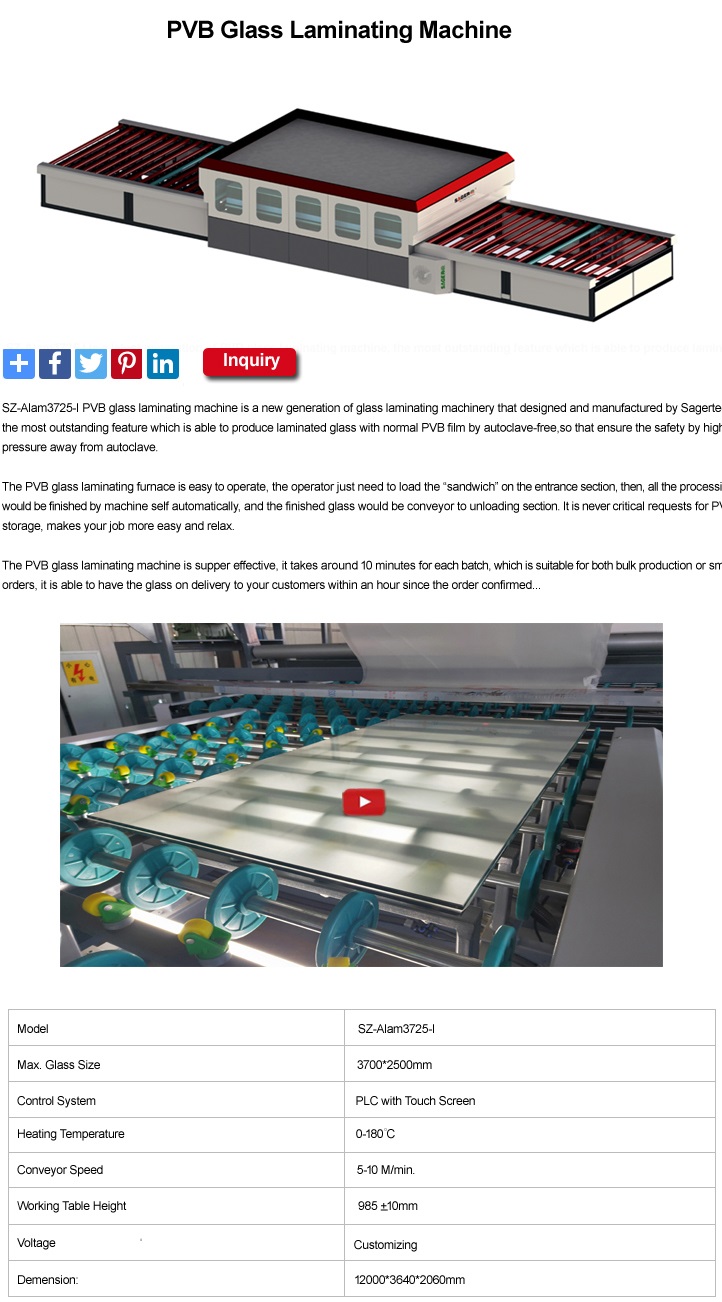

Complete Laminated Glass Production Line without Autoclave

The PVB Glass Laminating Line is a fully integrated laminated glass production line designed to produce PVB laminated glass without using an autoclave.

This innovative non-autoclave laminating technology eliminates the need for high-pressure processing, while still ensuring excellent optical clarity, adhesion strength, and long-term durability.

The line is composed of a loading table, glass washing machine, assembly tables, vacuum pre-laminating section, film holder, and an autoclave-free PVB glass laminating furnace, followed by the unloading table.

Each unit is precisely coordinated through intelligent control to guarantee stable and efficient operation.

This system is suitable for both mass production and custom laminated glass processing, providing a cost-effective and space-saving alternative to traditional autoclave systems.

Main Features & Advantages

- Complete non-autoclave PVB laminating line

- Integrates washing, assembly, vacuuming, laminating, and unloading

- High optical quality and strong adhesion of laminated glass

- Compact layout and low energy consumption

- Simple operation and easy maintenance

- Ideal for architectural, safety, decorative, and solar laminated glass

Typical Configuration:

Loading Table → Washing Machine → Assembly Table → Vacuum Device → Film Holder → Non-Autoclave Laminating Furnace → Unloading Table

| Model | SZ-Alam3725-II-L |

| Max.Glass Size | 3700*2500mm |

| Control System | PLC with touch screen |

| Heating temperature | 0-160℃ |

| Conveyor Speed | 5-20 M/Minute |

| Working Table Height | 985±10mm |

| Voltage | Customizable |

| Dimension | 32*5*2.8M |